October 17, 2024

Today AI has been considered as one of the promising technologies after the internet. And of course why not!

Due to its human-like advanced decision-making ability and problem-solving skills, it isn’t surprising that industries such as manufacturing are readily adopting AI technology.

The fusion of artificial intelligence in the manufacturing industry has brought about a transformative shift in industrial processes, leading to increased innovation across the manufacturing sector.

In fact, it is a boon for smart manufacturing as AI not only controls and automates its core processes but also identifies defects in parts and improves the quality of manufactured products.

But how the fusion of the artificial intelligence market in the manufacturing industry is the potential decision?

Well, with so much data being produced daily by industrial IoT and smart factories, artificial intelligence has several potential uses in manufacturing.

Manufacturers increasingly turn to AI, ML, and deep learning neural networks to better analyze data and make decisions.

In fact, predictive maintenance, supply chain management, digital twins, cotbots are some examples of AI in manufacturing that often showcase their critical role in the industry. Although there aren’t just these 4, there are more in the line.

Below in this post, we have shared a detailed guide on artificial intelligence in the manufacturing industry examples. Keep reading!

Artificial Intelligence Market In The Manufacturing Industry

So, before beginning with the example of AI in the manufacturing sector, let’s start by understanding the artificial intelligence market in the manufacturing industry.

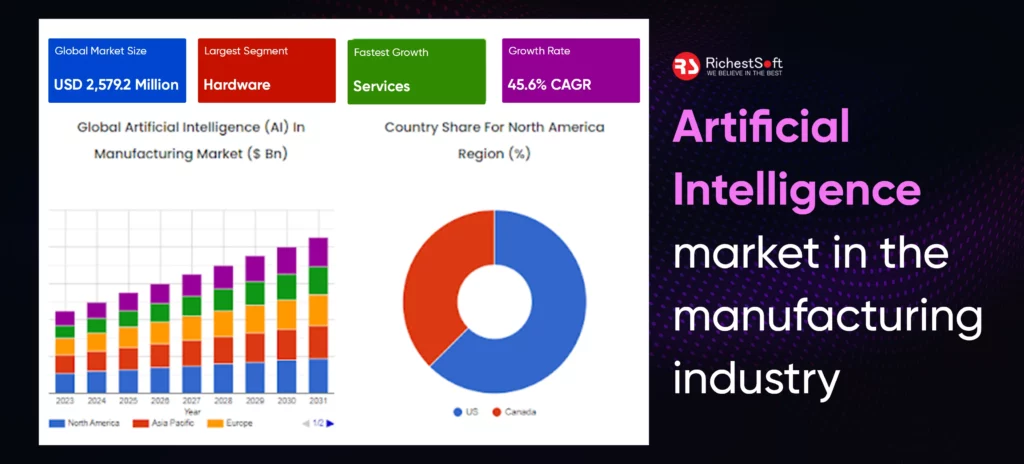

As per the reports of Sky Quest, the artificial intelligence market in the manufacturing industry size was valued at USD 2.58 Billion in 2022 and is expected to grow from USD 3.20 Billion in 2023 to reach USD 64.63 Billion by 2031 at a CAGR of 45.6% during the forecast period (2024-2031).

This significant growth indicates a rising adoption of AI in the manufacturing industry.

Advancements in AI technologies enhance efficiency, productivity, and decision-making in the industry.

Here is the market snapshot of the artificial intelligence market in the manufacturing industry from 2024 to 2031

Top 9 Use Cases Of AI In Manufacturing

So, here comes the important part—artificial intelligence in the manufacturing industry examples! Entrepreneurs can enjoy several benefits from implementing AI in the manufacturing industry.

Do you want to know how? Below, we have shared the top 9 use cases with their examples of AI in manufacturing. Keep reading below!

1. Predictive Maintenance

Predictive maintenance, with its AI applications, could potentially revolutionize the manufacturing industry. AI enables the manufacturing business to anticipate and proactively monitor equipment failure, reducing downtime and improving maintenance schedules.

It uses cutting-edge machine learning and predictive analytics techniques to achieve this.

This usually revolves around the “digital twin,” a virtual asset that depicts a sustainable asset activity and records real-time data. In fact, the production-level AI can combine the sensor data with the digital twin to identify trends and anomalies and predict potential errors.

These digital twins improve the overall performance of the production line, pinpoint energy losses, and optimize the manufacturing process.

With examples of AI in manufacturing, like advanced analytics and digital twins, AI’s predictive maintenance revolutionizes manufacturing, enhancing efficiency and cost-effectiveness.

2. Supply Chain Management

AI helps businesses in the manufacturing industry reinvent their supply chain operations, generating huge gains in accuracy, efficiency, and cost-effectiveness.

Using an AI supply chain increases the possibility of enhancing demand forecasting, streamlining logistics, and effective inventory control.

Machine learning algorithms examine past data, identify trends, and precisely predict changes in demand. Auto parts manufacturers utilize ML to predict demand, maximize inventories, and reduce expenses.

3. Cotbots

AI-driven production requires Cobots (collaborative robots), which boost output by assisting human operators. These cobots, which use AI algorithms to detect objects and navigate complex locations while working with human workers, assist with packing and selection at fulfillment facilities.

This cooperative strategy ensures optimal equipment performance, lowers maintenance costs, and minimizes downtime. Since they boost efficiency by assisting human operators, collaborative robots, or cobots for short, are crucial to AI-driven manufacturing. They assist with packing and selecting other tasks when working in fulfillment facilities.

Manufacturing businesses can utilize cobots empowered by machine learning to expedite order fulfillment, optimize logistics, and refine operational processes. These AI-infused robots exhibit precision and adaptability when executing complex tasks.

4. Quality Assurance

Higher levels of precision and consistency are being ushered in by the integration of AI in manufacturing, which is transforming quality control methods. Manufacturers use AI technology to examine photos or videos of items and components using computer vision algorithms.

These algorithms perform better than humans in detecting flaws, irregularities, and departures from quality norms with unmatched accuracy.

Predictive quality assurance is another area where AI trends in manufacturing are present. By examining both past and present sensor data, machine learning algorithms identify patterns and trends that may point to possible quality problems.

By taking a proactive stance, manufacturers can anticipate problems and take corrective action before adversely affecting the quality of the finished product.

Quality assurance is one of the examples of AI in manufacturing that ensures AI systems use picture and video analysis to quickly and accurately identify defects in electronic components, guaranteeing that strict quality criteria are met.

This application of AI enhances production efficiency and accuracy, empowering manufacturing businesses to deliver high-quality goods at scale.

5. Warehouse Management

With AI-powered solutions, warehouse management in the industrial sector is being transformed by increasing accuracy, efficiency, and cost savings.

Artificial intelligence (AI) improves inventory management by precisely predicting demand using sales data, inventory levels, and market trends. This optimization can minimize carrying costs and increase product availability.

6. Assembly Line Optimization

AI plays a key role in assembly line optimization, which improves industrial processes’ flexibility, efficiency, and accuracy.

Machine learning algorithms also enable predictive maintenance, save downtime, and optimize workflow by evaluating historical performance indicators and real-time sensor data.

By spotting defects or abnormalities, computer vision systems powered by AI guarantee the quality of the product.

Intelligent automation reduces waste and maximizes resource use by modifying production parameters in response to changes in demand.

Through constant learning and adaptation, AI creates data-driven and adaptable settings, which increase productivity, reduce costs, and maintain strict production standards.

7. Inventory Management

Inefficient inventory management can cause overruns in manufacturing businesses. Manufacturers can use AI technology to manage order records, update them, or add or delete inventory.

AI supports the manufacturing process by forecasting demand fluctuations and supply planning.

However, based on the market data and seasonal tendencies, AI-powered tools can easily predict customer demand for specific goods. With that information, manufacturers can plan supply and resource utilization and efficiently respond to the demand.

The use of AI in the manufacturing industry has resulted in some substantial breakthroughs in warehouse management.

8. Digital Twins

A digital twin is a virtual representation of the production facilities, services, and products. This virtual representation matches the physical attributes of its real-world counterpart by using sensors, cameras or other data collection methods.

Manufacturers integrate innovative components that gather past data about the physical item’s real-time condition, status, or position. These components are connected to a cloud-based system that receives and processes all the manufacturing data.

Construction firms can use digital twin technology to analyze building performance and adjust as necessary to boost efficiency. This is made possible through digital twins’ snapshots of their physical counterparts.

The stored data is transmitted to a remote human operator who can see the twin’s suggestions. Suggestions are commonly issued when the digital twin detects a problem and wants to offer solutions or potential improvements to the human operator.

9. Additive Manufacturing

Additive manufacturing, also known as 3D printing, assembles products layer by layer. It differs from conventional manufacturing, which involves material removal. AI in industrial automation facilitates 3D printing as well.

It ensures that good designs are made and that materials are used appropriately. AI for manufacturing companies can also correct real-time design errors during printing.

Let’s understand it with the example of 3 in the toy sector. It seamlessly made it possible for designers, even kids, to create and print their own kind of toys.

Objects can be drawn, or 3D files designed elsewhere can be imported to create custom printable CAD designs.

5 Manufacturing Industries Influenced by AI Integration In Their Apps

So, there is no doubt that the manufacturing industry is at the forefront with the artificial intelligence.

Want to know how? Here, we are discussing the role of artificial intelligence in the Manufacturing industry:

1. Automotive Industry

AI can improve the precision and accuracy needed in the automotive manufacturing industry. Ford, for instance, uses cobots to perform welding, gluing, and quality monitoring. In thirty-five seconds, it can sand an automobile’s whole body using six cobots.

Comparably, BMW’s Spartanburg facility, which produces 60% of BMWs sold in the United States, employs AI-managed robots to reallocate personnel and save $1 million annually.

By 2027, it is anticipated that the automotive AI industry would reach $7 billion, making it one of the industries pioneering the use of AI in production.

2. Electronic Industry

AI can play a key role in reducing production errors, enhancing product design, and shortening time to market in electronic manufacturing, which also demands precision because of its complex components.

For example, Samsung’s South Korea plant uses mechanical arms, robots, and automated vehicles (AGVs) for quality inspections, material transportation, and assembly for phones like the Z Flip 5 and Galaxy S23.

These instruments can assist businesses in upholding strict quality requirements, such as by examining between 30,000 and 50,000 components.

To save time and provide more control over cost and speed, Nvidia is utilizing AI to optimize the placement of complex transistor layouts on silicon substrates. It optimized a design with 2.7 million cells and 320 macros in under three hours, demonstrating its effectiveness.

Enhanced use of AI involvement is becoming a primary objective for electronics organizations because of the large market and ongoing progress in AI.

3. Aerospace And Defense Industry

Producing exact components increases system safety and performance, while AI-driven production improves product safety and reliability.

Forecasted to develop at a compound annual growth rate (CAGR) of more than 20%, the aviation AI market was valued $686.4 million in 2022.

With Neural Concept’s technology, Airbus was able to reduce the hour-long aircraft aerodynamics prediction time to 30 milliseconds using machine learning.

With this type of productivity improvement, design teams may be able to investigate 10,000 more modifications in the same amount of time as opposed to the conventional computer-aided engineering method.

Similarly, Rolls-Royce employs AI in aircraft manufacturing with the Blue Data Thread concept in partnership with IFS.

This method increases the time until the first engine removal by 48% by using digital twins and artificial intelligence (AI) for predictive maintenance.

4. Food And Beverage Industry

The “high-speed” nature of food and beverage production necessitates sophisticated quality assurance, especially in the fast-moving consumer goods (FMCG) industry.

That can be hampered by defective products and equipment, but integrating AI can improve productivity, affordability, product quality, and safety.

There is a specific demand for startups that specialize in predictive maintenance technology.

Consider Augury Inc. as an example. Four Frito-Lay factories saw reduced unplanned downtime and expenses because of their predictive maintenance systems, which allowed PepsiCo’s Frito-Lay to add 4,000 hours of manufacturing capacity annually.

5. Pharmaceutical Industry

Well, talking about the role of AI in the pharmaceutical industry, let us tell you that it usually takes ten years to develop a medicine and an additional two years to commercialize.

Unfortunately, 90% of medications fail at the clinical testing stage, which restarts the clock. But not anymore. AI is a promising technology that will improve quality control and hasten the creation of new drugs.

For example, Pfizer reduced computational time by 80% to 90% by using IBM’s supercomputing and AI to design the COVID-19 medication Paxlovid in four months.

Here are three of the areas where AI can alleviate drug-discovery challenges:

- Protein Structure Prediction: AI systems have helped researchers accurately understand the blueprints of complex molecules, possibly saving years of labor-intensive lab effort. This has completely changed the field of protein structure prediction.

- Function Forecasting: Artificial intelligence (AI) models can forecast the actions of huge molecules and comprehend the binding and movement of proteins and antibodies, which can improve the creation of therapeutic responses.

- New Therapies Design: AI systems create proteins, antibodies, and mRNA structures for illnesses like cancer by utilizing enormous amounts of data. For instance, Genesis Therapeutics employs AI to create and forecast the efficacy, specificity, and possible side effects of novel medications.

Using AI to discover new treatments might result in 50 new medications and $50 billion in sales over the course of ten years.

Pharma behemoths are investing in over 80 businesses that are pushing AI-driven medication discovery.

Blend The True Potential of AI in The Manufacturing Industry Via RichestSoft

Artificial intelligence has no wonder revolutionized the manufacturing industry in various aspects.

However remember while ai in the manufacturing industry is doing it’s level best, to fully understand it’s impact, a manufacturing business will definitely need a support of custom AI development experts, which is none other than the RichestSoft.

RichestSoft’s provides the finest AI integration services and has expertise in developing cutting-edge AI and ML products specifically tailored for manufacturing businesses has positioned the company as a leader in the industry.

In fact, we develop data driven logistics and supply chain management using AI-powered Robotic Process Automation (RPA), and analytics. We at RichestSoft Drives innovation and create custom AI/ML solutions that redefines the manufacturing industry standards.

Manufacturing business unleashes the full potential of AI and Machine learning by partnering with us, which leads to a great transformation and stand out in this competitive environment.

Wrap Up

So, this all you must know about the role of ai in the manufacturing industry.

We hope our provided artificial intelligence in the manufacturing industry examples and use cases has helped you understand the powerful role of ai in the manufacturing industry.

However, remember to get the true potential of artificial intelligence in the manufacturing industry you will need experts like RichestSoft!

We are the reputable AI service provider that will help manufacturing entrepreneurs to build their name in the industry.

Whether you are looking for a AI integration services or AI powered app for for your business we sincerely help you reach your objective goals. So, look no further contact us now!

+1 315 210 4488

+1 315 210 4488 +91 99888 06489

+91 99888 06489